Coal Control

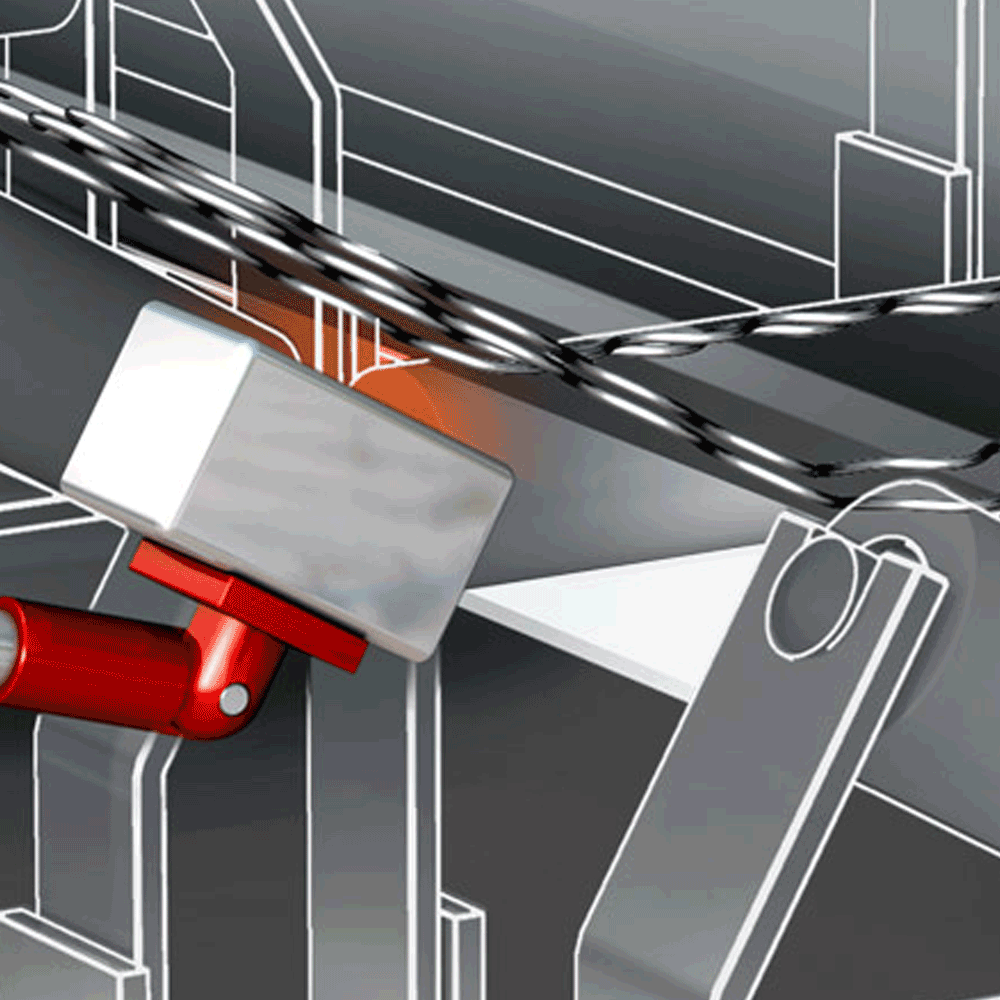

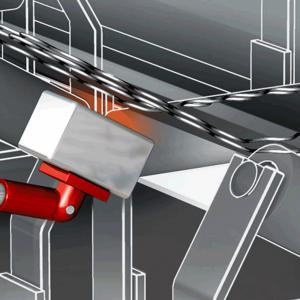

RIP CONTROL

Do you use steel cord or textile belts to convey your materials and have you often experienced longitudinal slits in your conveyor belt or do you not want to experience this at all?

Then Coal Control can help you and minimize your belt damage and the economic damage to a manageable risk.

Why do you need a tape slot detection system?

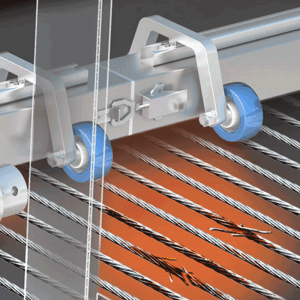

Foreign objects can damage both steel cord belts and textile belts. For monitoring conveyor belts, Coal Control offers a way of protecting danger spots on a conveyor.

Danger points are the points on a belt conveyor where the belt is loaded and unloaded. These points pose a particularly high risk of a seatbelt rupture.

A belt split occurs largely as a longitudinal split caused by foreign objects lodged in the conveyor belt or belt construction. For the most part, not only does the damage to the conveyor belt have to be taken into account, but also the time during which production has to be stopped in order to carry out the repair.

Coal Control belt rip detection systems can minimize a potential longitudinal tear to a limited distance and save you that hassle. Conductor loops, which are vulcanized into the belt conveyor, are evaluated with the help of the belt slit detection systems and ensure a possible shutdown in order to avoid a larger longitudinal tear and to keep the economic damage as low as possible.