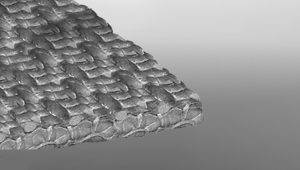

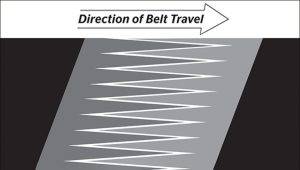

| Innovative fabric weave

The new dual-layer twill fabric gives Fortress XP improved load bearing and impact resistance. |

|---|

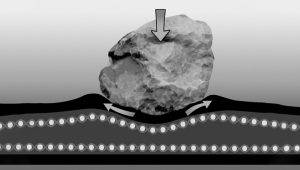

| Exceptional impact resistance

Fortress XP has industry-leading impact resistance. Loading point impact damage can be a major cause of belt failure. Design engineers used an enhanced Dynamic Impact Tester to simulate loading impact force and its effects on belting. |

|---|

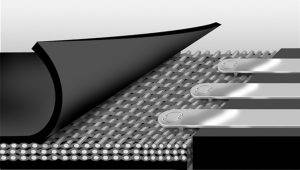

| High transverse tear strength

The dual-layer twill fabric design enables high transverse tear strength. This minimizes tears that result from material punctures as well as edge tears from misaligned belts. |

|---|

| Superior rip resistance

Scrap metal or debris often get “hung up” in the structure of the conveyor, causing equipment damage and slits or cuts in long sections of the belt. Our fabric design helps dislodge and expel foreign objects and contains rips to a small area. |

|---|

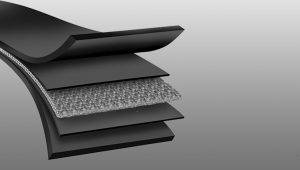

| Enhanced mechanical fastener pull-out resistance

Rigorous dynamic and static testing means that Fortress XP belts will provide superior mechanical fastener retention as compared with multi-ply and straight-warp constructions. |

|---|

| Vulcanized finger splice

A full carcass finger vulcanized splice is recommended for Fortress XP belting. This splice method takes advantage of the superior strength properties of the Fortress XP carcass to offer 100% of the rated belt tension. |

|---|