In 1964, the first FLEXOWELL® conveyor belt opened up a new dimension in bulk material handling and conveying.

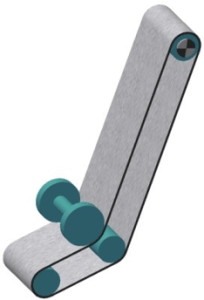

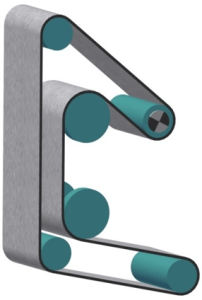

The FLEXOWELL® conveyor system being capable of running both horizontally and vertically, or at any angle in between, allows heavy duty conveying systems with large capacities to be designed, constructed and maintained

at considerably reduced initial and maintenance cost.

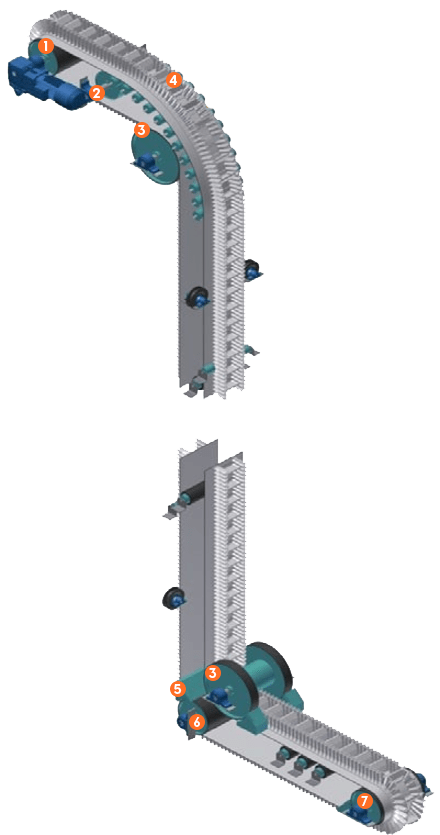

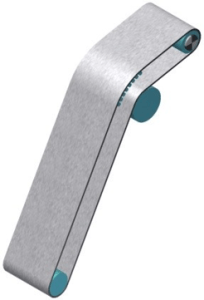

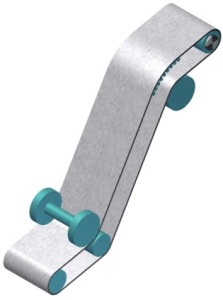

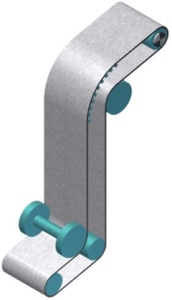

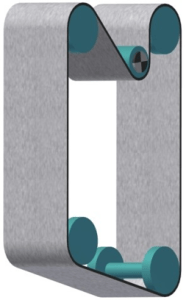

Today the FLEXOWELL® technology – being reliable and environmentally friendly – is in use in more than 15,000 installations throughout the world for the benefit of our customers. The vertical FLEXOWELL® S-system shown

on previous page is only the most populare sample of the large variety of conveyor shapes for complete bulk material handling solutions at any angle from 0° to 90°.

| 1 Drive pulley 2 Belt cleaning device 3 Deflection Whell 4 Deflection curve 5 Scrapper 6 Deflection Pulley 7 Take up pulley |

FLEXOWELL® conveyor belts can be integrated into complex conveying processes and ensure a continuous

conveying performance without further transfer points.

The advantages provided to plant engineers and operators are:

Sustainable solution:

Maximum reliability is granted by FLEXOWELL® conveyor belts

thus ensuring an environmentally friendly operation in all kinds

of industries as:

|  |  |  |  |  |  |  |