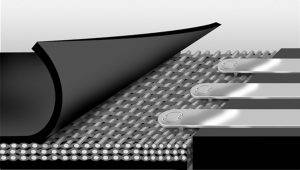

| Excellent fastener holding retention

High strength fill cords enhance mechanical fastener holding ability and resist fastener pull-out for reliable performance and increased uptime. |

|---|

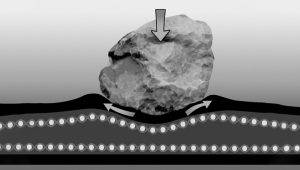

| Excellent rip, tear and impact resistance

Specially designed crimped warp cords straighten on impact and then recover their original shape. This enables the fabric to absorb greater impact loads and resist tearing for long-lasting durability and a lower cost-per-ton conveyed. |

|---|

| High ultimate strength

ContiFlex Plus withstands severe tension spikes at start up, retains mechanical fasteners and withstands continuous flexing around pulleys. This higher ultimate strength makes a critical difference in abusive operating conditions. |

|---|

| Reduced stretch

The combination of fabric design and dip process provides lower elasticity and permanent elongation on all specifications. This minimizes take-up concerns and reduces the number of splices at break-in. Contact your local Sales Representative to calculate permanent and elastic elongation requirements for your specific systems. |

|---|

| Standard bias step splices

A quick and effective technique, step splices greatly reduce downtime and are recognized throughout the industry as the standard. The vulcanized splice in ContiFlex Plus retains 100% of belt tension rating during all running conditions. |

|---|

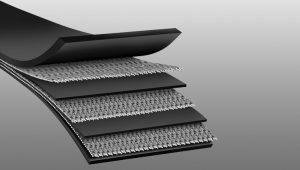

| Variety of cover compounds and cover gauges Protect your product with the proper compound and cover gauge for the application. ContiFlex Plus has the flexibility to customize a belt to your application. |

|---|

| Variety of fabric carcasses

Choose from a selection of carcasses that provide outstanding strength, adhesion, impact absorption and other properties. |

|---|